Complete sourcing guide for On-The-Go Stick Sunscreen including supplier directory, FOB pricing, product specifications, and market validation.

Verified Suppliers

1

Sourcing Strategies

0

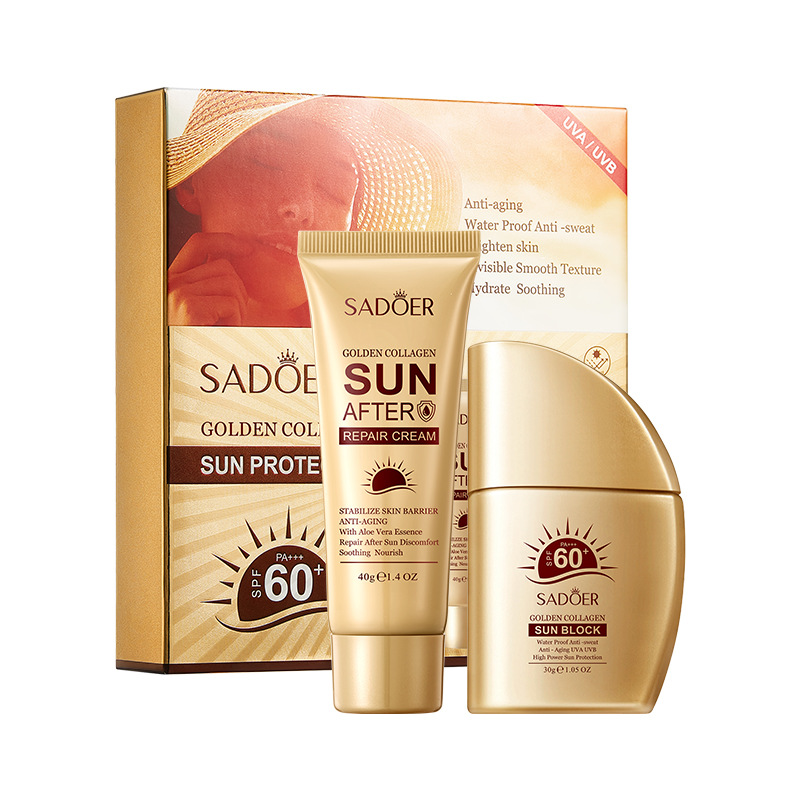

AI-generated product visualizations for On-The-Go Stick Sunscreen

A quick preview of supplier standards, production requirements, and sourcing intelligence from our verified network.

Verified suppliers with years of experience and quality strengths

| Supplier | Images | Tier | Years | Response | Favorites | Key Strengths | Product Expertise | Shop Ratings | Contact |

|---|---|---|---|---|---|---|---|---|---|

Xingfu Biotechnology (Guangdong) Co., Ltd. No. 15, Industrial Cluster Development Zone, Xiamao Town, Sihui City, Zhaoqing, Guangdong | Tier 2 | 3+ | 0.55% | 1.2k | Good DisputeGood Service | Sheet MaskLiquid EssenceFace Cream | Quality 3.3 Returns 3.3 Logistics 3.0 Consult 3.0 Dispute 4.0 Overall 4.0 | View contact |

0 verified suppliers across 0 manufacturing hubs

Average Ratings Across All Suppliers

0.0

Quality

0.0

Logistics

0.0

Returns

0.0

Disputes

0.0

Support

0.0

Overall

Top-tier verified manufacturers with quality ratings and capabilities

| Company | Tier | Years | Quality | Logistics |

|---|---|---|---|---|

| Xingfu Biotechnology (Guangdon... | TIER 2 | 3+ | 3.3 | 3.0 |

Tip: Click on a supplier row to see detailed ratings breakdown. Ratings above 4.0 indicate reliable suppliers.

The final cost of a sunscreen stick is primarily driven by the formula, specifically the type and concentration of active SPF ingredients. Optimizing the formula offers the highest cost-saving potential, followed by simplifying the primary packaging and increasing the order volume to achieve better economies of scale.

Confidence: High| Pricing Lever | Cost Impact | Quality Risk | MOQ Impact | Lead Time | Notes |

|---|---|---|---|---|---|

| Switch from Mineral (ZnO/TiO2) to Chemical/Hybrid Actives | ↓ Medium–High | Medium | - None | - None | Mineral actives are often more expensive. This impacts 'clean beauty' claims and may require reformulation for stability. |

| Lower SPF from 50+ to 30 | ↓ Medium | Low | - None | - None | Reduces the required concentration of expensive active ingredients. May impact market competitiveness as SPF 50 is preferred. |

| Simplify formula (remove non-essential additives) | ↓ Low–Medium | Low | - None | - None | Removes ingredients like Vitamin E, Hyaluronic Acid, etc. This reduces cost but also limits marketing claims. |

| Use stock packaging vs. custom mold | ↓ High | Medium | ↓ Medium | ↓ High | Eliminates high tooling costs and long lead times. The product may look less unique and stock components can vary in quality. |

| Remove secondary packaging (retail box) | ↓ Medium | Medium | - None | ↓ Low | Reduces cost and waste, but offers less protection in transit and less space for branding and regulatory text. |

| Increase MOQ (e.g., from 5k to 10k+) | ↓ Medium–High | Low | ↑ High | - None | The most effective way to lower unit price. Unlocks better pricing for both the formula and all packaging components. |

| Reduce fill weight (e.g., 20g to 15g) | ↓ Low–Medium | Low | - None | - None | Directly reduces the amount of formula used per unit. May affect consumer perception of value. |

Ready to formulate your perfect sunscreen stick? Contact us to connect with certified manufacturers and optimize your cost-to-quality ratio for the Brazilian market.

The most critical risks for stick sunscreens involve formula stability (melting), SPF efficacy, and texture. Packaging functionality is also a common point of failure that can ruin the user experience.

Confidence: HighRoot Cause

Unstable formula with a low melting point; improper wax/butter ratio; lack of climate-controlled shipping.

What to Specify / Ask Supplier

Require formula stability test results (e.g., stable at 45°C for 30 days). Specify requirement for climate-controlled logistics.

QC Check (What "Good" Looks Like)

Place a sample in a 45°C oven for 24h. Check for oil beads (sweating), softening, or shape loss.

Root Cause

Formulation error; insufficient or poor dispersion of active ingredients; batch-to-batch inconsistency.

What to Specify / Ask Supplier

Request third-party in-vivo/in-vitro SPF test report for the formula. Require a Certificate of Analysis (CoA) with active ingredient % for each batch.

QC Check (What "Good" Looks Like)

Review the batch CoA. For large orders, send a sample from the production line for independent lab testing to verify SPF.

Root Cause

Poor dispersion of mineral actives (ZnO/TiO2); ingredient crystallization; incorrect wax selection.

What to Specify / Ask Supplier

Define desired texture ('smooth, non-gritty glide'). Approve a pre-production 'golden sample' to be used as the standard.

QC Check (What "Good" Looks Like)

Apply the stick to the back of your hand. It should feel smooth with no graininess or excessive drag. Compare against the golden sample.

Root Cause

Cheap twist-up mechanism; poor assembly; formula leaking into components.

What to Specify / Ask Supplier

Specify quality grade for the container. Ask for component supplier details and functional test reports.

QC Check (What "Good" Looks Like)

On a sample of units, twist the mechanism fully up and down 20 times. Check for jamming, slipping, or breakage.

Root Cause

Ineffective preservative system; unsanitary production environment (not cGMP compliant).

What to Specify / Ask Supplier

Require manufacturer to be cGMP certified. Request microbial challenge test results (PET) for the formula.

QC Check (What "Good" Looks Like)

Review the microbial testing section of the batch CoA. Visually inspect for discoloration/mold and smell for any off-odors.

Root Cause

Poor emulsification; ingredient incompatibility; exposure to extreme temperatures (freeze/thaw).

What to Specify / Ask Supplier

Request full stability data, including freeze-thaw cycle testing.

QC Check (What "Good" Looks Like)

Visually inspect the stick surface for cracks or oil pools. Cut a sample in half to check for a homogenous internal structure.

Root Cause

Large particle size of mineral actives (Zinc Oxide/Titanium Dioxide).

What to Specify / Ask Supplier

Specify requirement for 'low white cast' or 'transparent' application. Ask about the particle size of the mineral filters used.

QC Check (What "Good" Looks Like)

Apply to skin and blend. Check for a visible white or purplish film under natural light. Test on multiple skin tones.

Ensure your sunscreen meets the highest standards. Partner with us to implement a rigorous QC plan and access pre-vetted, cGMP-compliant factories experienced with ANVISA regulations.

Use this data to create your product specifications, reach out to suppliers, and validate your pricing strategy. Start with small sample orders to test quality.

Real product samples with pricing, MOQ, and supplier ratings

| Product | Title | MOQ | Price (CNY) | Price (USD) | Sale QuantityHow many units sold | OrdersHow many orders in Alibaba/1688 | Rating | Tiered Pricing | Key Features | Link | Action |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cross-border foreign trade SADOER bone collagen anti-wrinkle body lotion moisturizing moisturizing cream bone collagen skin care products series | 120 | ¥2.20 | $0.37 | 635,740 | 520 | 3.3 |

| SADOERGlycerinNormal Size | Source Item |

This sourcing playbook provides actionable guidance for importing On-The-Go Stick Sunscreenproducts. Our data-driven approach combines supplier intelligence with market validation to help you make informed purchasing decisions and minimize sourcing risks.

First orders typically require 30-50% deposit with balance before shipment (T/T). As relationships develop, suppliers may offer 30/70 splits or even open terms for established buyers. Letter of Credit (L/C) is available for larger orders but involves additional fees.

Document issues with photos immediately upon receipt. Most suppliers offer replacement or credit for legitimate defects within agreed AQL limits. Having clear quality specifications in your purchase order strengthens your position in disputes.

Third-party inspection is recommended for first orders and orders over $10,000. Services like SGS or Bureau Veritas cost $200-400 per inspection and can prevent costly quality issues. Pre-shipment inspection is most common; in-line inspection adds additional assurance.

Navigation: All Categories → Sunscreen → On-The-Go Stick Sunscreen → Sourcing