Complete sourcing guide for Airless Pump Cosmetic Tube including supplier directory, FOB pricing, product specifications, and market validation.

FOB Price Range

$58.35 - $201.38

Verified Suppliers

1

Sourcing Strategies

2

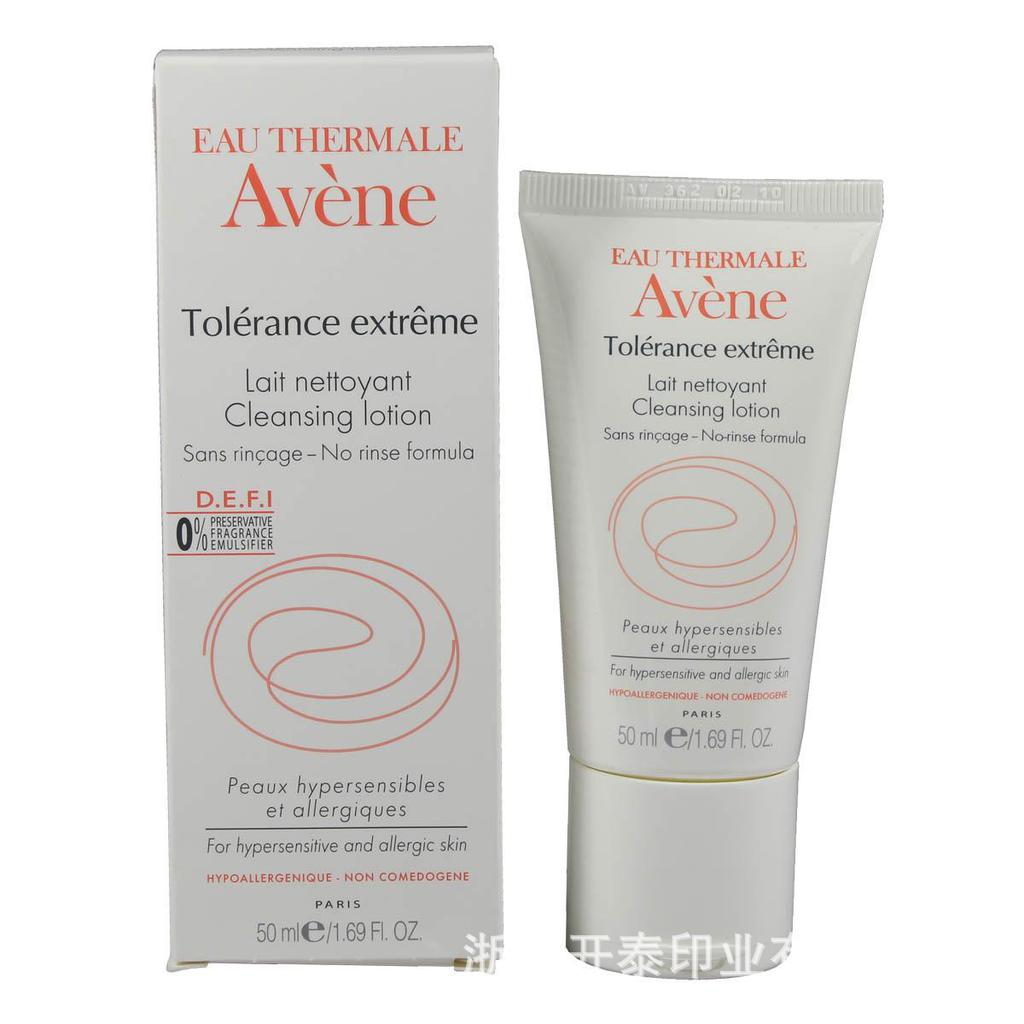

AI-generated product visualizations for Airless Pump Cosmetic Tube

A quick preview of supplier standards, production requirements, and sourcing intelligence from our verified network.

Verified suppliers with years of experience and quality strengths

| Supplier | Images | Tier | Years | Response | Favorites | Key Strengths | Product Expertise | Shop Ratings | Contact |

|---|---|---|---|---|---|---|---|---|---|

Zhejiang Kaitai Printing Co., Ltd. Zhejiang Wenzhou Cangnan County Longgang City Small Packaging Industrial Park Building 1 Unit 1 | Tier 4 | 5+ | 0.71% | 377 | Excellent QualityLow ReturnsGood DisputeGood Service | Paper PrintingPaper BoxPlastic Box | Quality 5.0 Returns 5.0 Logistics 4.1 Consult 3.0 Dispute 5.0 Overall 4.5 | View contact |

0 verified suppliers across 40 manufacturing hubs

Average Ratings Across All Suppliers

0.0

Quality

0.0

Logistics

0.0

Returns

0.0

Disputes

0.0

Support

0.0

Overall

FOB pricing by manufacturing cluster, compare costs across regions

| Region | Suppliers | Min FOB | Avg FOB | Max FOB |

|---|---|---|---|---|

| Bangcheng Factory, Henan Province, Xinxiang City, Yuanyang County, Zhulu Township, Zhongyuan Printing Industrial Park Phase II | 1 | ¥1 | ¥1 | ¥1 |

Top-tier verified manufacturers with quality ratings and capabilities

| Company | Tier | Years | Quality | Logistics |

|---|---|---|---|---|

| Zhejiang Kaitai Printing Co., ... | TIER 4 | 0+ | 5.0 | 4.1 |

| Supplier | Yrs | Rating ↓ | Actions |

|---|

Tip: Click on a supplier row to see detailed ratings breakdown. Ratings above 4.0 indicate reliable suppliers.

To effectively manage costs for airless pump tubes, the primary levers are material selection and construction. Moving from premium dual-wall acrylic to single-wall PETG or PP offers the most significant savings. After material, simplifying the pump mechanism and decoration method provides the next tier of cost reduction.

Confidence: High| Pricing Lever | Cost Impact | Quality Risk | MOQ Impact | Lead Time | Notes |

|---|---|---|---|---|---|

| Switch material from Acrylic (PMMA) to PETG | ↓ Medium–High | Medium | - None | - None | Reduces the 'heavy, glass-like' feel but maintains excellent clarity and good durability. |

| Switch material from PP to AS (with increased wall thickness) | ↓ Low–Medium | High | - None | - None | AS is more brittle than PP, increasing the risk of cracking even with thicker walls. A significant quality trade-off. |

| Change from dual-wall to thick single-wall construction | ↓ Medium | Medium | - None | ↓ Low | Reduces weight and the premium feel but simplifies production and lowers material cost. |

| Use standard-duty pump instead of high-viscosity engine | ↓ Medium | High | - None | - None | High risk of pump failure if the formula is thick. Only viable for thin lotions and serums. |

| Opt for silk-screen printing instead of hot stamping or metallization | ↓ Low–Medium | Low | - None | ↓ Low | Reduces decorative cost but changes the aesthetic from metallic/shiny to a flat print. |

| Use stock colors (white/clear/black) instead of custom Pantone match | ↓ Low | Low | ↓ Medium | ↓ Medium | Avoids custom color compounding fees and lowers MOQ requirements significantly. |

| Remove accessory kits (funnel, spatula, pouch) | ↓ Low | Low | - None | ↓ Low | Simple way to reduce cost and packaging complexity, but lowers perceived value. |

| Increase MOQ (e.g., from 3k to 10k units) | ↓ Low–Medium | Low | ↑ High | - None | Unlocks better price breaks on raw materials and molding efficiency. |

Ready to find the perfect balance of quality and cost? Submit a sourcing request with your target specs, and we'll connect you with vetted suppliers for your airless pump tubes.

The most critical failure points for airless tubes are pump malfunction, body cracking, and leakage. These issues stem from poor material choice, weak pump mechanics, and imprecise molding, leading to significant customer complaints.

Confidence: HighRoot Cause

Weak spring; poor piston seal; pump engine not suited for formula viscosity.

What to Specify / Ask Supplier

Request pump cycle-life test data (e.g., >500 actuations). Specify formula viscosity (cps) and require a compatible pump engine.

QC Check (What "Good" Looks Like)

Fill a sample with a similar viscosity liquid. Actuate 30-50 times. Check for consistent dosage and no jamming.

Root Cause

Using brittle plastics like standard AS or PS; thin wall design; molding stress.

What to Specify / Ask Supplier

Specify durable materials like PP, PETG, or thick-walled AS. Define a minimum wall thickness (e.g., 1.5mm).

QC Check (What "Good" Looks Like)

Drop test a filled, capped bottle from 1 meter onto a hard surface. Inspect for cracks or stress marks.

Root Cause

Poor thread molding; missing or low-quality gasket; improper cap fit.

What to Specify / Ask Supplier

Require a screw-on cap with a silicone gasket. Specify a vacuum leak test as part of the QC protocol.

QC Check (What "Good" Looks Like)

Fill with water, cap tightly, and leave upside down for 24 hours. Squeeze gently to check for leaks around the collar.

Root Cause

Poor ink adhesion; incorrect curing; incompatible finish for the plastic type.

What to Specify / Ask Supplier

Specify the decoration method and require an adhesion test standard (e.g., 3M Scotch 610 tape test).

QC Check (What "Good" Looks Like)

Firmly apply and rip off a piece of strong adhesive tape from the decorated area. No ink should come off. Rub with a cloth.

Root Cause

Inner plastic material reacting with cosmetic ingredients (oils, alcohols); metal spring corroding.

What to Specify / Ask Supplier

Specify a chemically resistant inner bottle (PP is common). For sensitive formulas, request a metal-free fluid path.

QC Check (What "Good" Looks Like)

Conduct a stability test: fill samples with the actual product, store for 4-6 weeks (ideally at 40°C), and check for bottle warping, discoloration, or formula changes.

Root Cause

Poor molding tolerances between the piston and the inner wall of the bottle; flashing or burrs.

What to Specify / Ask Supplier

Specify smooth, burr-free internal surfaces and provide tolerance requirements for inner diameter.

QC Check (What "Good" Looks Like)

On an empty bottle, manually push the piston from top to bottom. It should travel smoothly without catching or requiring excessive force.

Root Cause

No verification of markings; using generic molds without checking capacity.

What to Specify / Ask Supplier

Require permanent, clear volume markings (e.g., '50ml / 1.7 fl oz') and request capacity verification.

QC Check (What "Good" Looks Like)

Use a graduated cylinder to fill the bottle to its intended capacity. Verify the liquid level and markings are accurate.

Don't let quality issues ruin your launch. Source with us to get a comprehensive QC checklist and access to inspection services for your airless pump tubes.

Use this data to create your product specifications, reach out to suppliers, and validate your pricing strategy. Start with small sample orders to test quality.

Real product samples with pricing, MOQ, and supplier ratings

| Product | Title | MOQ | Price (CNY) | Price (USD) | Sale QuantityHow many units sold | OrdersHow many orders in Alibaba/1688 | Rating | Tiered Pricing | Key Features | Link | Action |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Factory supply design color printing cosmetics facial cleanser carton | Batch printing white cardboard color box | 3000 | ¥0.61 | $1.90 | 0 | 0 | 0.0 |

| KAITAI0.1kgNo | Source Item |

Choose from 2 pricing strategies based on your target market

This sourcing playbook provides actionable guidance for importing Airless Pump Cosmetic Tubeproducts. Our data-driven approach combines supplier intelligence with market validation to help you make informed purchasing decisions and minimize sourcing risks.

First orders typically require 30-50% deposit with balance before shipment (T/T). As relationships develop, suppliers may offer 30/70 splits or even open terms for established buyers. Letter of Credit (L/C) is available for larger orders but involves additional fees.

Document issues with photos immediately upon receipt. Most suppliers offer replacement or credit for legitimate defects within agreed AQL limits. Having clear quality specifications in your purchase order strengthens your position in disputes.

Third-party inspection is recommended for first orders and orders over $10,000. Services like SGS or Bureau Veritas cost $200-400 per inspection and can prevent costly quality issues. Pre-shipment inspection is most common; in-line inspection adds additional assurance.

Navigation: All Categories → Cosmetic Tube → Airless Pump Cosmetic Tube → Sourcing